LU Jiangyi

Mechanical Engineer / Product Designer

Quick-release Foot Strap For Minimizing Injuries During Sailing Races

bACKGROUND / PROJECT GOALS

In 49er and Nacra 17 classes sailing competitions, our injury surveillance studies documented increasing injury rates with the introduction of faster boats to competitions.

One of our findings is that current rigid foot straps put enormous strain on sailors’ knee, ankle and foot during sudden deceleration caused by inevitable accidents and collisions. This is due to the rigid root strap on the boats which constraint the sailors’ foot to the boat while the sailors’ body continues to be flung forward due to the inherent momentum.

The goal of this project is to design, develop and evaluate a mechanized foot strap device that will seamlessly continue to provide leverage during normal sailing operations but allow the sailor to be safely ejected from the boat during emergencies and accidents. This mechanism is fully mechanical and utilizes the body’s momentum for activation and operation.

DESIGN IDEAS

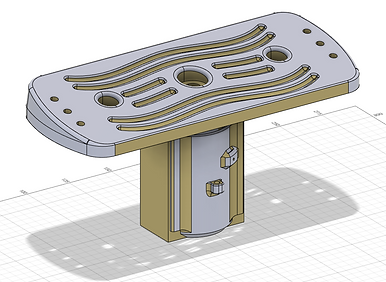

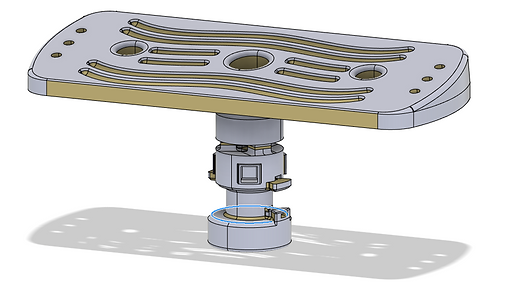

As shown, the device will be mounted at the end of the boat shell. Most components of the device are produced using special materials 3D printing (Carbon fibers)

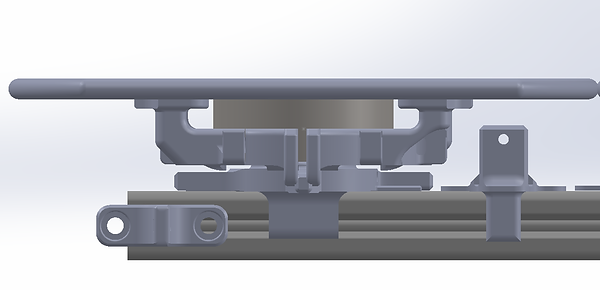

A strong spring is the most essential component. One end is attached to the arm of the pedal. The other end is attached to the bracket which is fixed in the extrusion. Totally there are 4 springs in each pedal. We will set up a threshold based on the user’s weight and then use this value to determine the intensity of the spring. Normally, the pedal will not rotate. When there is a collision, the pedal will rotate with the foot and the spring will make the process very smooth to ensure the safety of the athlete. Following figures are the CAD of the initial prototype design.

ImPROvement of proTOTYPES

Currently, we have updated our prototype. The initial prototypes got 2 main problems. First one is the whole structure is too big. The space in the pedal is limited. Usage of aluminium extrusion is not suitable for users' requirements. The second one is the durability. Since the structure works in water, the exposed design can cause corrosion of key components. Based on this, we came out the second prototypes. The CAD of the improving prototype and working videos are here also.